Fortunately, as much as converting a mesh to a solid is a complicated operation, the contrary, converting a solid to a mesh, is very straightforward. So we will need to convert any object we want to 3D print into a mesh first, that the slicer can open. None of the slicers will, at this time, directly take the solid geometry as we produce in FreeCAD. But we will see how to export and use these slicers to check that the output is correct.

These programs usually offer advanced configuration possibilities that allow you to tailor the output exactly for the features of your 3D printer.Īctual 3D printing, however, is too vast a subject for this manual. Since many of those printers are home-built, there are often small differences from one to the other. The 3D object is exported to another program (the slicer) which will generate the G-code from the object, by slicing it into thin layers (hence the name), which will reproduce the movements that the 3D printer will do. This is the technique most commonly used for 3D printing. We will now see how to address the third point. When printing in 3D, you must always make sure this loss of quality stays below your minimum requirements.īelow, we will assume that the first two criteria are met, and that by now you are able to produce solid objects with correct dimensions. In any case, some loss of quality of your model will unavoidably occur during the process.

The conversion of your models into G-Code can be easy and automatic, but you can also do it manually, with total control over the output. G-code has dozens of different dialects, each machine or vendor usually has its own. Most of them will only understand a machine language called G-Code. No 3D printing or CNC milling system can take FreeCAD files directly. One millimeter will be one millimeter in real-life.

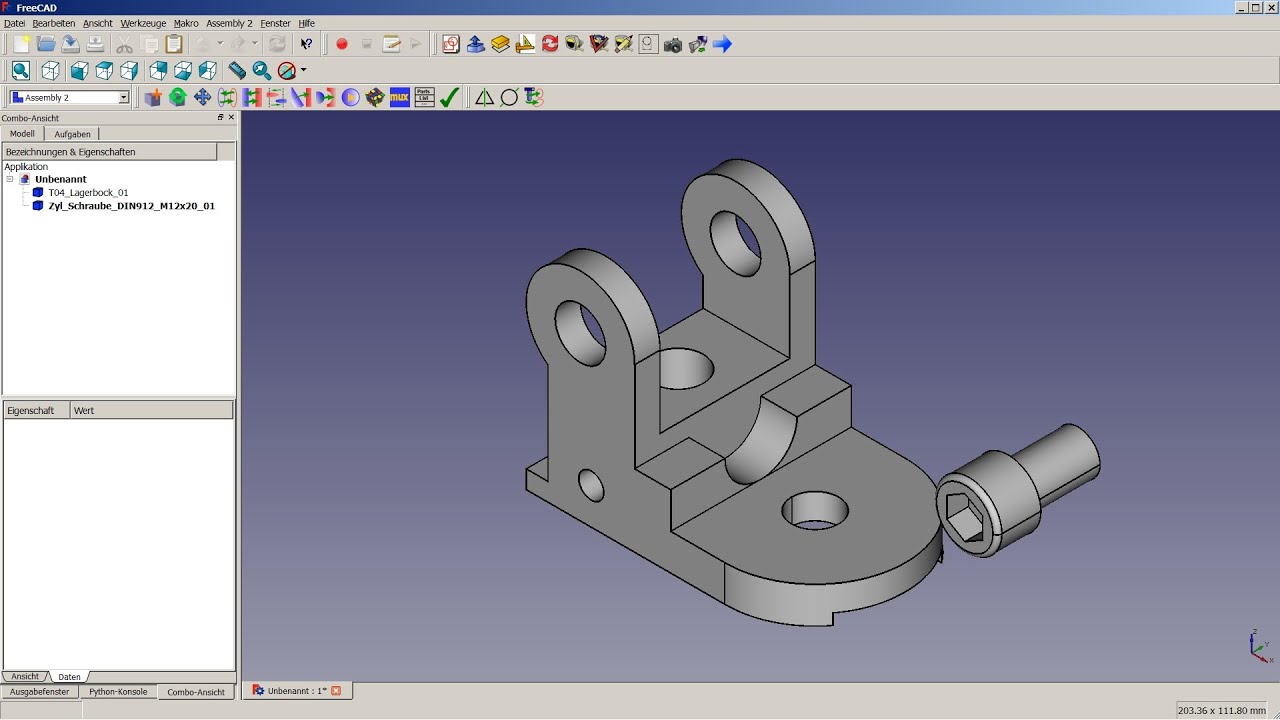

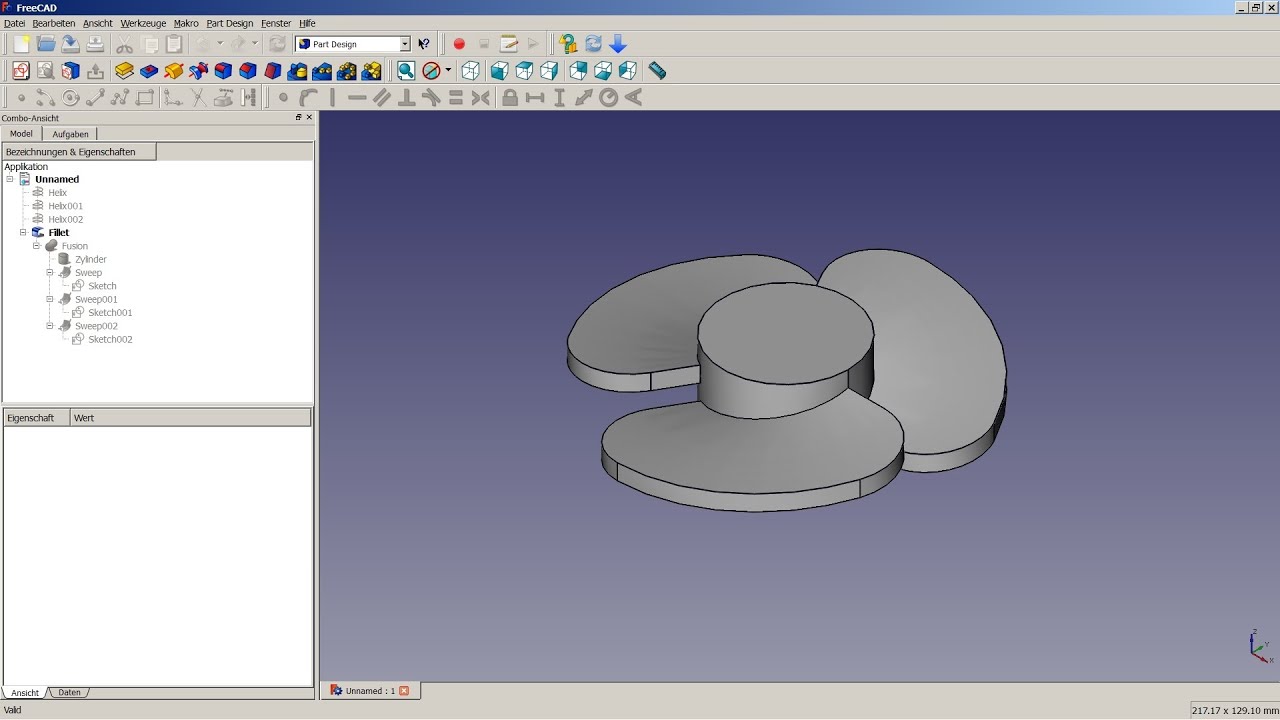

If you have been cautious while modeling, most of the difficulty you might encounter when printing your model in 3D has already been avoided. This chapter will show you how to get your models ready to send to these machines. These can be designed in FreeCAD, and then made real in different ways, such as communicated to other people who will then build them, or, more and more frequently, sent directly to a 3D printer or a CNC mill. One of the main uses of FreeCAD is to produce real-world objects.

0 kommentar(er)

0 kommentar(er)